This additional function allows to run optimizations without setting in advance a target feeding rate.

As previously explained, it is

possible to input a target feeding rate before running the optimization of the

composite.

However, this step is not strictly necessary since we have introduced a feature

that allows the system to automatically define the target feeding

rate. If the current feeding rate

(ultimately the amount of the base recipe) matches the target feeding rate, the

optimizer tries to find a

feeding rate amount that gives enough extra space for the feeds to meet the constraints. In other

words, the algorithm is able to self-define the minimum necessary feeding

rate, with a variable safety margin, based on the constraints set.

This can be helpful when, before the optimization, it is not clear which amount should be entered, to obtain an optimal solution without leaving too much space (e.g. a target feeding rate set too high could result in a composite with an unnecessarily high amount of substrate).

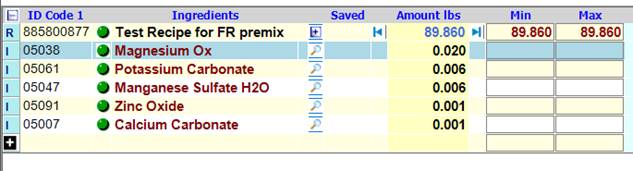

In the

previous example, the target feeding rate was set to 90.0 lbs. Running the

optimizer without entering a desired target feeding rate we have the

following:

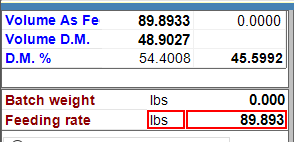

Notice how the solution has a lower amount of substrate (Calcium Carbonate): 0.001 lbs vs 0.105 lbs, a consequence of the lower feeding rate target: 89.893 lbs vs 90.0 lbs.

After evaluating the solution, you can consider keeping the feeding rate amount or changing it and run the optimization again in order to get its desired feeding rate. You could also manually add a fixed amount of a composite ingredient as a “carrier” such that a specific As Fed amount is provided to bring the final composite to a desired feeding rate.