The information needed to start the process need to be inputted both in the Maximum yield and in the Production step text boxes.

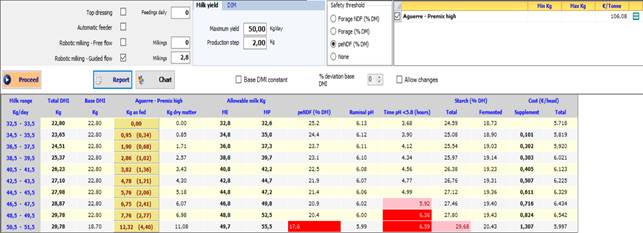

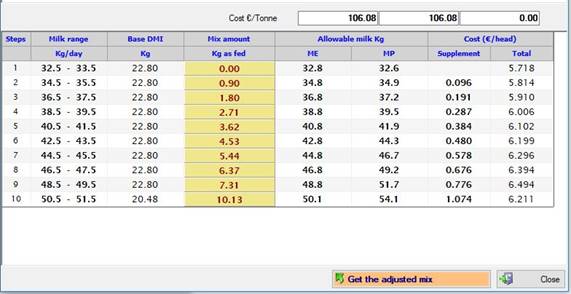

After providing these values, it is possible to click on the Proceed button to start the calculations. This could take a while to complete, depending on the data of the recipe and the entered values. The results are displayed in a list in which each step is as a single row, with its suggested amounts for the feeds (base diet and step feed(s)) and some diet parameters obtained by the model calculations, which give information about the performance and possible well-being risks.

Notice that the first row of the list always shows the initial (current) values for the recipe; if the step feeding process cannot be carried on (e.g. due to incomplete data) only the first row with the initial values will be displayed.

Minima and Maxima for the Step Feeding feeds

For the feeds involved in the step feeding process, it is possible to input a range, limited by a min and a max. It means that, during the step feeding process, the amounts set for each feed will be taken inside of the defined range. It is also possible to input just a min or a max, leaving the other cell of the row empty.

Minima and Maxima can alter the behaviour of the step feeding process, so it is recommended to choose these values very carefully, in order to avoid unexpected results. Since the amounts of the feeds generally increase at each step, a min set too high can determine the failure of the process during the first steps, while a max set too low can negatively influence the process during the last steps. In these cases, it is always worth running the procedure with unconstrained feeds, to check if the minima and maxima were set at critical values.

Step Exit Condition

Ideally, the procedure stops when the Maximum yield is reached. Each step should provide a recipe with a total DMI fitting the DMI standard curve, an allowable milk (ME and MP) within the related step range, and some biological parameters (forage, rumen pH, starch) defined to describe the level of nutritional health obtained at each step, in accordance with the Well-being criteria. When this is not possible, the procedure tries to produce a recipe that is a good compromise among these factors.

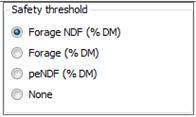

However, in order to provide solutions with acceptable nutritional sense, one nutritional safety threshold can be chosen among some pre-defined parameters and the selection of the parameter is possible through a radio button group:

The parameters considered are listed below and the safety values are customizable through the Well-being risks defaults panel in the Utility tab:

- Forage NDF on a dry matter basis;

- Conventional forage content on a dry matter basis;

- Physically effective NDF on a dry matter basis.

A fourth option (None) allows to remove any threshold exit condition.

Based on one of these three different parameters, the procedure will determine the exit from a certain step, that will be the last step, once the chosen threshold value is exceeded, even though Maximum yield is not reached.

In other words, once a criterion is selected, a threshold based on the Well-being related critical minimum is set, which, if reached, will create the conditions to stop the search of the results during a certain step because, once the threshold value is reached, further steps will probably have a value under the threshold. In the list of results, a column shows the values for each step of the selected option. If the fourth option is selected (no exit condition), the columns shows the values of Forage NDF by default.

A further background condition based on the total starch parameter can determine a correction of the amounts of the involved feeds. The goal of this correction is to limit the total starch, keeping its value under (or around) the critical maximum set into Well-being risks management.

Manually adjustment of Step data

For some practical or strategic reasons, it may help to change manually both basal diet DMI and step feeds amounts. Thus, was introduced the possibility to manually adjust some data in the result panel, inputting desired values. Before starting editing the cells, it is necessary to check the Allow changes checkbox in order to make the cells changeable. Notice that, when the checkbox is checked, the list of the feeds is not editable. In the lists of results, only some columns are changeable:

- The Base DMI column (on dry matter basis)

- The columns of the step feeding feeds amount (values both on as fed and on dry matter basis)

- The Forage NDF or Forage column (% DM), based on the safety threshold selected

Each time a value is changed, the row related to the step is updated with the new data. The Total DMI, related to the standard DMI curve, is not affected by these changes, so the added to or subtracted amount is compensated, to keep it unchanged; more specifically, if a certain amount is added to the Base DMI, the same amount on dry matter basis will be subtracted from the other feed(s) and vice-versa. Similarly, if a certain amount is added to a step feed, the same amount will be subtracted from the Base DMI and vice-versa.

Some other features are available here:

1. Base DMI constant: allows base ration (PMR) to be held at constant amount according the current level;

2. % deviation base DMI: allows to give a % deviation of PMR so that it can change from 1 to 10%;

3. Variation DMI: allows total DMI to increase holding PMR constant. It happens when % deviation base DMI is set to zero

Fine tuning of Step Feeding Mixes

When a mix (created in the recipe or formulated through the Composite module) is included in the step feeding feeds list, a feature is available (after the first run), to check if its composition can be enhanced, in order to obtain better results from the step feeding process. In other words, the system tries to make some adjustments to the current mix, using the same ingredients included, with the aim of proposing, provided it is available, an alternative mix composition that should better meet the production goal for each step, both for ME Milk and MP Milk.

More in detail, the main goals are:

1. Keeping ME allowable milk near the centre of the Milk range at each step.

2. Minimizing the difference between ME allowable milk and MP allowable milk at each step.

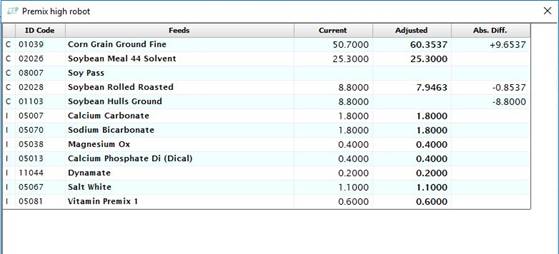

A pop-up form displays the results of the step feeding process obtained with the new mix, along with the comparison between the old and new compositions; the user can decide if the new mix should replace the current one in the recipe.

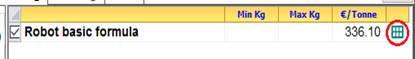

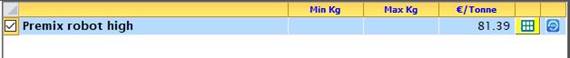

To run the mix elaboration, you have to click on the image button in the last cell of the row of the selected mix (the command is ineffective with the encrypted composites). Notice that this becomes visible only after the step feeding process has run, since the elaboration uses data obtained during the main step feeding process.

The elaboration requires some time to complete, depending on the number of steps in the main process and the number of ingredients of the mix. A green progress bar shows the state of advancement of the elaboration; this consists of two steps: one for creating the alternatives for the mix and the other to simulate the step feeding process and select the best one; this is why the progress bar fills two times before completion.

If the system finds a valid alternative for the mix (this won’t always be possible), a pop-up form displays the results; otherwise, a message informs that the system has not found any better mix. Note that if the initial mix is already well suited for the step feeding process, only marginal differences, if any, can be expected; moreover, the cost of the alternative mix in some cases could be higher than the initial one.

In the upper part of the form there is a comparison between the initial composition of the mix and the alternative one; the values are as fed percent amounts, with the difference in the last column.

In the lower part of the form, under the comparison of the costs of the two versions, the results of the step feeding process obtained with the alternative version are displayed.

To accept the new mix, click on the Get the adjusted mix button; this will update the composition of the mix in the recipe and update the results of the step feeding output screen.

If two mixes are simultaneously included in the step feeding feed list, it is possible to run the elaboration on both mixes, one by one, clicking on the related buttons. Obviously, in this case, the results of the first elaboration can affect those of the second, if the alternative for the first mix is accepted before to run the adjustments for the other mix.

Once accepted the alternative composition for the selected mix as described above, it is still possible to restore the initial mix, using the button in the last column of the grid:

![]()

Notice that this button becomes visible only after the alternative composition for the mix is accepted. This command restores the mix as it was before running the fine-tuning feature for the first time; anyway, if the mix is saved after accepting an alternative composition, the command is removed from the grid.