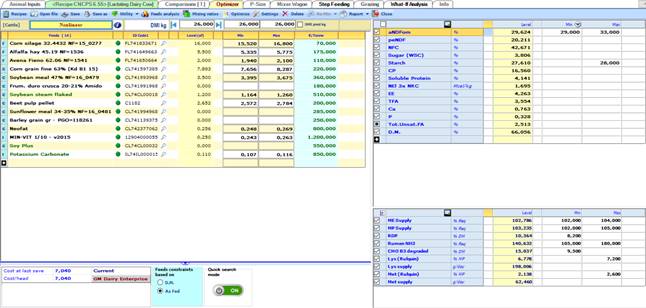

The Nonlinear optimization is a goal-oriented dynamic formulation system (or non-linear biological model) returning rations according to the objective selected, choosing the best in the context of a wider range of possible solutions.

In this section you can:

− select the objective of optimization

− set mins and maxes on feeds

− set mins and maxes on nutrients analysis

− set mins and maxes on model parameters

− set mins and maxes on DMI

− add or change feeds costs

− add or remove feeds

− add or remove nutrients

− input feeds constraints in term of Dry Matter or As Fed basis

Pressing Optimize will start the calculations process having as a result, when the problem is feasible, a number of optimal solutions, according to the objective of optimization, and sensitivity analysis.

Among the recipes shown in the tab, you can choose what is considered the most appropriate or change the constraints and re-run the process.

Conditions for enabling the ration optimization button

Ø Minimum and Maximum DMI must be defined (other than 0)

Ø For each feed in the specifications, the minimum must not be greater than the maximum

Ø The sum of the feed minimums must not exceed the total maximum (corresponding to Max DMI)

Ø The sum of max must not be less than the total min (if there are feeds without a max this rule is ignored)

Ø At least one valid constraint must be set for nutrients (NB: a minimum of zero is considered valid, a comparison is made between the content of the variable and an empty string, in the flex, the empty cell is displayed even if the minimum is zero)

Ø If in a ration the total DMI is reset the button is disabled. In the case where one starts from scratch (with feeding rates = 0), even though DMI is zero, the button remains enabled instead.

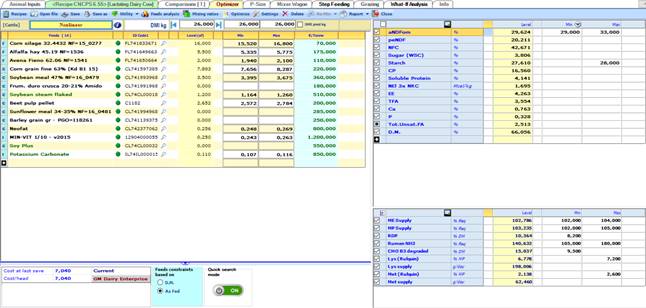

Automatic generation of constraints in the nonlinear optimizer

a) Regenerate specification: feed constraints are recalculated regardless of whether or not they have an existing constraint

b) Regenerates user constraints: the constraints that have a value > 0 are recalculated; the "free" constraints (no values sets) are not recalculated, that is, they remain unassigned.

In summary, this function performs the following operations:

1. It performs a pre-optimization using the current constraints (the volume is set on the DMI value of the ration if it is inside the constraints, otherwise it takes the average value between Min and Max DMI)

2. If the pre-optimization is feasible (optimal or sub-optimal) a range of variation is calculated for each feed based on an algorithm specifically developed

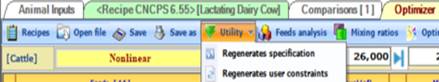

Type of solutions

The Nonlinear optimizer has the potential to return always one or more solutions.

Solutions returned can be of two types:

− optimal solution

− sub-optimal solution

Optimal solutions: are combinations of feeds meeting all the constraints we set for ingredients, analytical and biological (model) parameters. The number of optimal solutions returned is definable in the Settings form.

When the optimizer returns more than one recipe, they are ordered according to the objective function. For example, if we have selected as objective the Minimum Ration Cost, the solutions are ordered in ascending order by cost ration.

It cannot tell if one solution is better than another for other reasons, for example, from a nutritional point of view, thus, the nutritionist has to make the final decision.

Sub-optimal solutions: are recipes that do not meet one or more constraints we set for ingredients, analytical and biological (model) parameters. This does not mean that the recipes are bad rations; they may just be outside of desired constraints and sometimes are more economical or efficient to use. This is where nutritional assessment is very important. If a diet is more economical and a constraint such as ME Supply (% Req.) is 99.8% vs. a desired 100.0%, is not necessarily a ‘bad’ result. In other words, sub-optimal are evaluated could be nutritionally acceptable but slightly less than desirable. Given the variation in parameter measurements and model variation, it is not possible to say that a 99.8% Req. is different than a 100% solution but the objective might be more advantageous.

The nutritionist has to review the returned solutions and evaluate if one of them is nutritionally and economically acceptable or decide to change one or more constraints, run again the optimization procedure trying to get better solutions.

The CNCPS model is intrinsically nonlinear because includes many nonlinear functions. Feed biological values vary with animal and feed characteristics, so the optimizer will seek optimal solutions, but if it cannot find any of them, will always propose several sub-optimal solutions, which are as close as possible to the constraints desired, particularly for the model parameters (non-linear).

Symbols description

For optimal and sub-optimal solutions tabs may appear some symbols described here:

![]()

Amount of feed or level of nutrient of the solution correspond exactly to their minimum constraint; it is respected but by reducing it can be achieved advantages or the optimizer might work better;

![]()

Amount of feed or level of nutrient of the solution correspond exactly to their maximum constraint; it is respected but by increasing it can be achieved advantages or the optimizer might work better;

![]() Amount of feed

or level of nutrient of the solution are lower of their minimum constraint;

it is not met and the solution is not optimal but

sub-optimal. You can try to reduce the minimum constraint giving the

optimizer better chances of finding optimal

solutions. To report

that value indicates one of the reasons why the solution is sub-optimal, the

cell is highlighted with a different back color.

Amount of feed

or level of nutrient of the solution are lower of their minimum constraint;

it is not met and the solution is not optimal but

sub-optimal. You can try to reduce the minimum constraint giving the

optimizer better chances of finding optimal

solutions. To report

that value indicates one of the reasons why the solution is sub-optimal, the

cell is highlighted with a different back color.

![]() Amount of feed or level of nutrient of

the solution are higher of their maximum constraint; it is not met

and the solution is not optimal but sub-optimal. You can try to increase

the maximum constraint giving the optimizer better chances of finding

optimal solutions. To report

that value indicates one of the reasons why the solution is sub-optimal, the

cell is highlighted with a different back color.

Amount of feed or level of nutrient of

the solution are higher of their maximum constraint; it is not met

and the solution is not optimal but sub-optimal. You can try to increase

the maximum constraint giving the optimizer better chances of finding

optimal solutions. To report

that value indicates one of the reasons why the solution is sub-optimal, the

cell is highlighted with a different back color.

However, it is very important that any changes in constraints on feeds or nutrients maintain nutritional and biological sense.

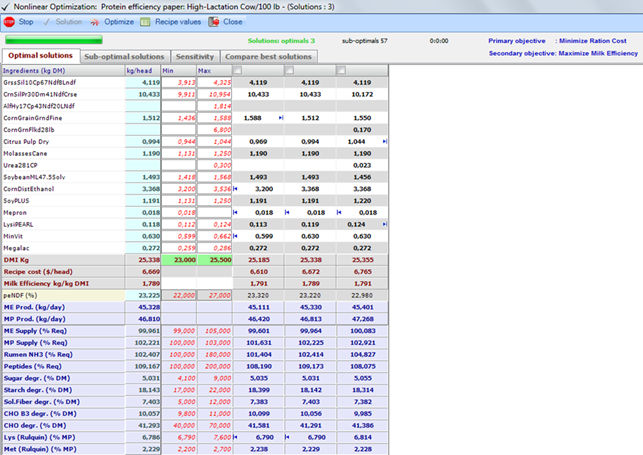

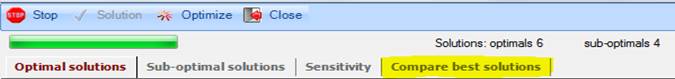

Compare best solutions

After the first optimization, you can click the Optimize button and re-running the optimizer with the aim to seek further solutions. NDS has the ability to store the best solutions of the previous optimization processes, ordered by a function calculated from the value of the objective and the violations of the constraints.

To display these solutions, click on the Compare best solutions tab. Be aware that the previous solutions are kept even if some constraints are changed by the user.

As well as for optimal and sub-optimal solutions tabs, you can get the recipe you think more interesting checking the relative column then Solution button.

Sensitivity

This tab displays the results of the sensitivity analysis, a feature able to help the user getting better solutions in terms of optimality or, in case of already optimal solutions, obtaining better objectives functions (e.g. lower cost).

Please consult the NonLin Sensitivity page for a more comprehensive explanation of the tool.

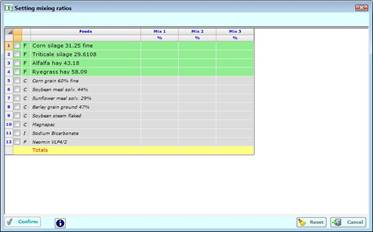

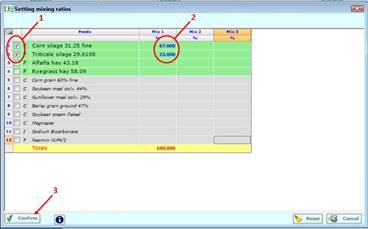

![]() Mixing ratios

Mixing ratios

This feature allows you to set ratios between feeds: you can specify the relative proportion among sets of feeds (maximum 3 sets). The optimizer will include the feeds specified by identifying their optimal amount according to the proportions asked for them.

Follow these simples steps:

1. check the feeds that should be included in ratio among them in the final recipe

2. entry the ratio of inclusion as a percentage

3. click Confirm button

Warning! Some of the constraints previously set on the feeds checked, could not be met because the optimizer considers, as a priority, the ratios requested.

Feeds constraints in Mixing Ratios

When a ratio is set, the proportions among the feeds are managed by the Optimizer as additional constraints. The existing min and max of the feeds included in the ratio could not be in accordance with these new constraints generated by the proportions; in this case, during the optimization, NDS will ignore that min and/or max to find solutions that satisfy the constraints based on the proportions.

The mixing ratios feature currently works only with the forages included in the specification.