According to our vision, based on recent research and observations, a correct formulation strategy for AMS system should consider below assumption:

− Increasing concentrate provision in the AMS will likely not improve milk yield or milk component yield;

− Energy dense PMR may increase DMI without negatively affecting voluntary visits;

− Amount of concentrate consumed should match that targeted;

− High AMS concentrate provision relies on frequent AMS visits, but increases variability in daily AMS concentrate intake;

− Low AMS concentrate provision strategies may allow for more flexibility for the type of feed used in the AMS.

So, a suggested approach to formulate an optimal feeding programs with AMS might be as follows:

a. Formulate the PMR for the pen average milk yield that includes the minimum amount of the robot pellets able to guarantee the proper number of visits to the robot for the average producing cows. This minimum amount should be around 1-1.4 kg (2-3 lbs) delivered through the robot and not included in the PMR. In this way, for the average pen milk yield we should have both for ME and MP allowable milk:

− PMR without AMS concentrate = 93-95 % Requirements

− PMR with minimum AMS concentrate = 100 % Requirements

b. Set the maximum amount of the robot pellets based on the maximum number of visits observed for high producing cow, considering following constraints:

− Maximum meal size of 1.5 kg/d (3.3 lbs)

− No carry-over

c. The above constraints should be set for all cows regardless milk yield and number of visits to the robot.

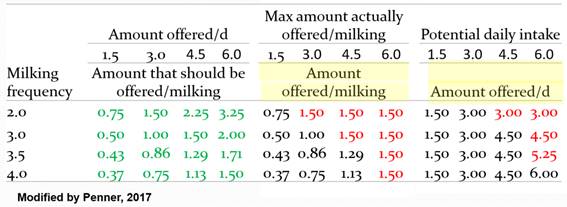

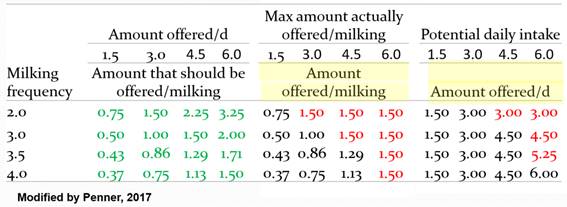

Based on milking frequency, the potential intake of AMS concentrate might be:

With this approach, let us suppose that a pen is milking 33 kg/day:

Ø I would formulate the PMR in order to allow 30 kg both for ME and MP

Ø I would include the minimum amount of robot pellet (1.4 kg) formulated with the goal to get the pen average milk yield (33 kg/day that is 100 % Requirements)

Ø If the observed maximum number of visits to the robot of high producing cow is 4, I would set the maximum amount of the robot pellets to 6 kg/day (1.5 x 4)

Ø I would check that maximum meal size constraint with no carry-over is set for all the cows visiting the robot.

To support the above strategy, let us report the conclusion made by S. B. Menajovsky et al., 2018 J. Dairy Sci. 101:1–13:

“….Our results indicate that the quantity of AMS concentrate offered reduces PMR intake with only marginal effects on milk and milk component yield, but feeding a greater amount of concentrate in the AMS increases day-to-day variability in AMS concentrate consumption, challenging the notion of precision feeding when simply increasing the amount of pellets offered in the AMS. In addition, providing a greater proportion of concentrate in the PMR may improve milk yield without increasing variability in PMR or AMS concentrate intake, but may result in reduced ruminal pH.”